A Lesson from Lean Thinking: Do Less to Get More Done

Think about the last time you answered an email while attending a meeting (we've all done it). Were you really able to craft a thoughtful response to that email and give your fellow meeting attendees the attention they deserved? It's unlikely -- in fact, psychologists say, it's impossible.

Now, consider the fact that much of your organization might be functioning with that level of distraction. This isn't just about the inability to give full attention to whatever task is at hand -- it's the inability to be intentional about which tasks you're doing, and how and why you're doing them.

When this happens across an organization, teams and individuals risk making decisions without considering their downstream impact. They complete work ad hoc, rather than focusing on work that's prioritized according to organizational goals. It's like a youth soccer game -- everyone knows to run to the ball, but they aren't necessarily employing a strategy for how to work together to score a goal.

In his book, How the Mighty Fall, author Jim Collins refers to this approach to work as "the undisciplined pursuit of more."

A Lean Strategy for Doing Less: Kanban and WIP Limits

If the problem is the undisciplined pursuit of more, then the logical solution is the disciplined pursuit of less. The key word in this phrase is disciplined -- a systematic, clear approach that helps organizations make smart decisions. Lean provides an excellent solution for this, with a workflow management tool called Kanban, and a strategy within Kanban called a WIP limit.

:: Kanban ::

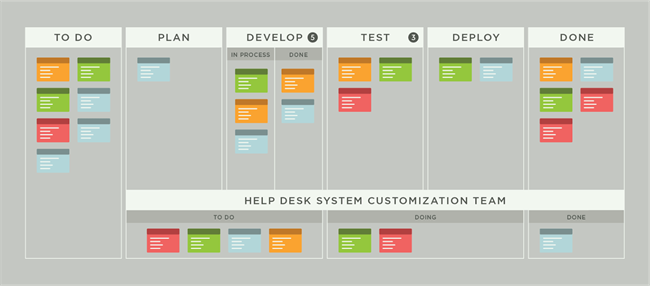

A sample Kanban Board, with WIP limits applied to "Develop" and "Test"

Kanban provides the disciplined approach that organizations need to begin doing less. It harnesses our brain's natural preference for visual information, representing work as cards that move across a whiteboard (called a Kanban board), which represents a team's process. Kanban boards are a team-based tool that can provide clarity at the organizational, team and individual levels. They can help teams stay aligned around priorities and focused on delivering value to their customers.

A typical Kanban board groups all the unique steps of a team's process into three primary stages: To Do, Doing, and Done. The "To Do" stage represents work that is in the backlog, waiting to be moved into "Doing." Work in the "Doing" stage is actively being worked on, and it moves to the "Done" stage when it reaches the customer.

The first step of practicing Kanban is to identify the steps in your process that fall within the three general stages of work. For example: Do you vet your work before starting it? If so, perhaps your process in the "To Do" stage is more accurately defined by the steps of "New Request," "Approval," and "Ready." For each step you identify, add a vertical lane until you've created a board that reflects your current process, from "To Do" to "Done."

:: WIP Limits ::

Once you have a Kanban board that reflects your process, you can begin to control how work gets prioritized and how it moves through your workflow. You can also begin to influence how much work is actively being worked on any given time -- this is a concept called limiting WIP, or work-in-process. It's common to apply a WIP limit to a lane with active work (e.g., any step in the "Doing" stage of your process), but a WIP limit can also encourage mindful prioritization when used in a backlog lane.

WIP limits can be implemented at the individual, team and organizational levels (and can be most effective if used at all three). At the individual level, this means that you can focus your efforts on finishing a handful of tasks with the highest quality and speed possible. At the team level, this means that teams can optimize the efforts across the team and work continuously to deliver the highest value. At the organizational level, this means organizations gain the clarity they need to align execution with strategy.

Achieve the Ultimate Goal: Continuous Delivery of Value

While narrowing your focus is a key part of practicing "Lean, Lean" thinking isn't only about doing less. The goal is to use doing less as a way to create more value. When doing less at once, you're able to approach work with more clarity, better focus and greater purpose. You can make decisions based on priority, executing toward clear, strategic objectives that support organizational goals. Most of all, you can deliver work that has a more meaningful impact on your customers.

About the Author

Maja Majewski is a content writer at LeanKit, where she creates educational tools to help teams and organizations grow in their practice of Lean and Kanban. She has been applying Lean and Agile principles to marketing for more than two years. Maja graduated from Vanderbilt University with a degree in Human and Organizational Development and Corporate Strategy. Connect with her on LinkedIn.

Maja Majewski is a content writer at LeanKit, where she creates educational tools to help teams and organizations grow in their practice of Lean and Kanban. She has been applying Lean and Agile principles to marketing for more than two years. Maja graduated from Vanderbilt University with a degree in Human and Organizational Development and Corporate Strategy. Connect with her on LinkedIn.

Subscribe to Our Newsletter!

Latest in Marketing